|

My comments are

in italics below

Bob:

Thanks for that great eye splice demonstration.

I found several ideas

to add to my toolbox of splicing techniques. I have a couple

of others

I would like to share with you. I stole these ideas fair and

square

from several others, so there is no shame in stealing them from

me if

you like.

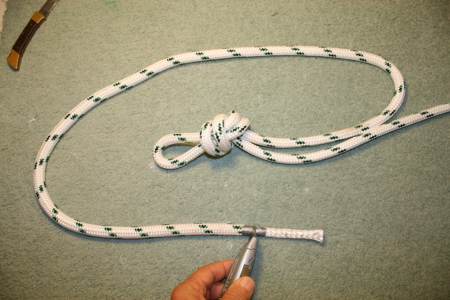

Instead of hammering on your splice, with

the attendant risk of damaging

some of the fibers and ending with an uneven distribution of

materials

inside the doubled section, lay the nearly finished splice on

a clean

floor and using your shoe sole roll the entire doubled portion

back and

forth repeatedly. This gentler pressure and repeated rolling

'works'

the uneven portions into place, whereas the hammer approach crushes

the

lumps without redistributing them laterally inside the outer

sheath.

This technique works fine for layed line splices as well as braid.

I did say use the hammer

gently and I got a letter from a dutch sailor that said the hammer

was actually traditional, but if you have good results rolling

with the shoe, go with what works for you but I do not think

use of the hammer as described is harmful to the ropes fibers.

Another trick to make feeding ends easier

and the finished splice

smoother is to cut core ends on as long a taper as you can. Wrap

the

section to be cut first with masking tape, use a razor blade

to make as

long a tapered cut as possible and immediately retape the resulting

tapered tip (or try the paraffin wax trick below).

Instead of taping the core end to the outside

of the original core (???) it

can be untaped and carefully worked into the interior and held

in place

with a couple of Sews Awl stitches across the point where it

last

entered the original core in place of the PVC tape that would

end up

buried at the bitter end of your splice. That, by the way is

where your

test splice broke, when the seizing/whipping tape that remained

inside

the sheath was not compressing as the line stretched, but instead

the

edge of that blunt end chafed the outer sheath fibers, initiating

the

failure.

The splice did not break.

The break was clear of the work and I really doubt the tape used

had anything to do with the break. I think it was caused entirely

by a few tons of steel in opposition to each other. There was

a change in mass at that point and when the whole unit is challenged

to the point of breaking, that is a likely spot.

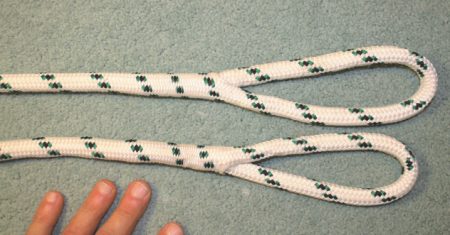

The spliced eye should always be made large

enough that the "Y" part

(the throat) is not splayed apart much when under strain. I often

seize

that area with waxed Sews Awl twine, secured at each of the three

ends

with several decorative back stitches.

Define "much"

but in genral I agree. I would express it as "too much".

And all the seizing work you describe shouldn't be required if

the splice is done correctly.

I have a big splicing project at hand making

all new fancy custom

mooring lines for my big boat, and I intend to experiment with

using

melted canning paraffin wax in place of tape to make the temporary

whippings. The melted wax can soak into the interior of the braid

(or

layed) line and bind all the fibers in place when it solidifies.

The

resultant wax/fiber is soft enough to be cut with a razor blade

or sharp

knife, can be molded to tapered/pointed shapes by hand and is

slippery

enough when cold (and wet) to pass easily through outer braid,

for

instance. When the splice is finished the wax can be removed

from the

interior with hot water, good

luck with that! and any remaining

will soften when the splice

heats under load, lubricating the interior, which might not work to advantage, preventing 'internal chafing.' Of course I don't

expect anybody to play with a pot of melted

wax in their sailboat cockpit, but at my workbench it should

work just

fine.

Your thoughts?

My thoughts? I think

thank you very much for adding to the knowledge pool! This page

is proof there are numerous ways to skin a kitty and some methods

will work better for some so all are valid. Find what is best

for YOU!

Gary Bell

34' power catamaran "Stray Cat" and

80' sidewheel paddleboat "Liberty Belle"

berthed in Multnomah Channel near Portland, Oregon |