|

|

Our first clue, the little rusted spot

I saw at pre-purchase inspection and brought to the surveyors

attention. He said not to worry, 'a little anti-foul over it

the next slipping' This slipping was two months later and when

I scratched the spot the screw driver went through!! I hired

a local engineer to patch the steel and replace the worn cutlass

bush. They managed to put a huge ugly patch on the hull that

I later replaced and in the act of repairing the bush,they bent

the shaft and wrecked the cutlass and stern tube. It became obvious

the jeweller was going to have to learn about boat repair. |

|

|

I asked the surveyor about the "bumps"

in the teak deck too. "Not to worry..." |

|

|

|

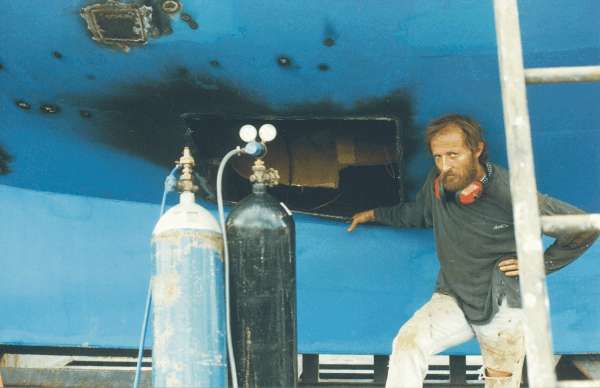

I have never doubted that I married

well. Kay was down below working and wasn't happy about this

photo but I wanted something to give a sense of scale to this

nightmare. There was no steel left under the teak. It was now

soil! |

|

|

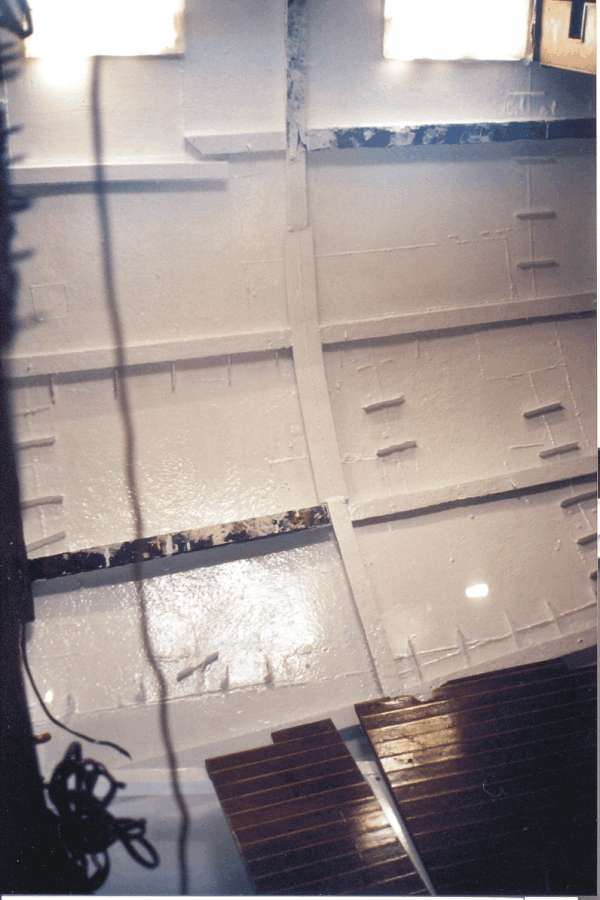

Cut the old out and weld the new in. This

is my first welding job.... EVER! The

first go I shaped the sheets of steel to perfection. All a perfect

tight fit. Zero gap between sections. This was a disaster of

course as the welds started cracking later. After cutting all

the seams again and leaving a 3 mm gap, I got great penetration

and very sturdy welds. Another lesson learned. |

|

|

|

I was pretty proud at this point and

figured I was half done....... Another lesson learned. |

|

|

Of course the bow was just as bad and

was all replaced too. The side decks were heavily repaired but

saved in large part. |

|

|

It looked OK under the cockpit seats...

but they had hidden the mess with a layer of fibre glass. This

shot is after I cut away the rotten combing. |

|

|

That's the cockpit... lovely eh? |

|

|

While I was at it I redesigned the whole

thing including a "light box" type thing to better

illuminate the Galley below. |

|

|

Progress.... The decks are now water

tight... so time to start below. |

|

|

I have read old books on steel boat

building saying how good blown in polyurethane insulation is

in steel boats... BULLSHIT! Water soaks it and retains it. the

steel was a mess under the crap. |

|

|

You can see some of my patches in this shot.

All the rotten foam gone, the steel scaled for days and a very

careful paint system installed. Lost count of how many layers

of paint. Two of pre prime, then a couple of epoxy primer, then

a couple coats of "jotomastic, then layer upon layer of

white polyurethane two part paint. about 12-15 coats in all.

|

|

|

The prop shaft on left and the shaft

tube in center was all replaced with much of the surrounding

steel. |

|

|

After... |

|

|

This is the low point in the bilge,

the water tanks had been here, preventing inspection and hiding

horrible sins. I had to cut them to pieces to remove them. We

held off scaling the rust back till the boat was on the slip,

good thing as the tool punched 8 holes through the steel. She

was floating on rust and paint!! |

|

|

The engine was very good but the cooling

system/ heat exchanger was stuffed. In fact everything that was

bolted on was wrecked. The uetectic fridge system was a disaster

and I threw that rotten thing away and never missed it. Electric

is the way to go!!!(below) |

|

|

|

I did the stainless work in sections

on the wharf. |

|

|

Then checked by eye with Kay holding

the bits in place. |

|

|

Experimenting with the plastic window

replacements. |

|

|

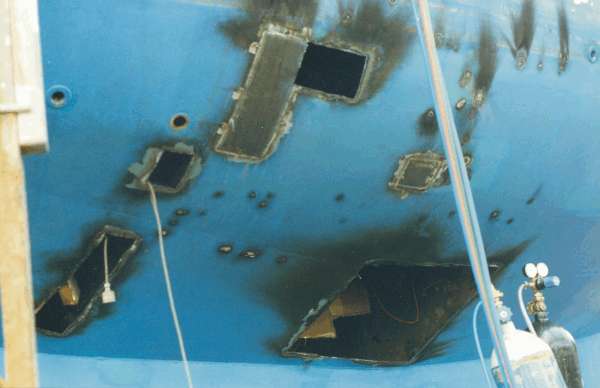

This was all done on the slip and the

fishermen didn't like the slip tied up for long so we did it

in one week periods max, three sessions. We had two welders then.

I would work on the inside after cutting the holes and rough

cutting the patches. Kay would work outside hammering in wedges

behind the dogs to roll the steel to the shape of the round hull

as I tacked the plate from the inside before welding all around

inside. When done with that, I would come out and weld the outside

bead with the other, more powerful welder. Over 40 sq FT were

done this way. By this time especially, my welding was very good.

Not one leak occured when relaunched. No weld has had to be serviced

in any way. |

|

|

Go ahead... ask me what I think of surveyors... |

|

|

Kay insures the paint is chipped back

to firm before a coat of primer. The burn marks where there are

no patches are where I found isolated worm holes in otherwise

good steel. I would just weld them up from the inside. |

|

|

Good! |

|

|

Now to repair the stuff the engineers

fucked up. I welded up a new stern tube out of schedule 80 stainless

pipe and 5/8 plate. |

|

|

Done! |

|

|

Didn't save them all but these are SOME

of the peaces of steel removed from under the water line. |

|

|

Good shit eh?! |

|

|

|

This is one of the water tanks I cut

apart to expose the bilge under the galley. It was holed (another

thing the surveyor missed) but notice it rotted from the outside

in!!! |

|

|

That pile of debris is rust scale. We

literally shovelled it out. |

|

|

It was surprising how thick the stuff

would get. |

|

|

When done the wood was kept to a minimum

and where it could be removed for service of the paint. Every

system of the boat was rebuilt and refurbished. All up 12

plates of steel (thats 1200X2400mm or 4" X 8") were

used in the repair and countless lengths of angle and bar. |

|

|

A

very good boat!... Now anyway. |